Modern asphalt pavement performance testing has evolved quickly. The physical testing procedures are relatively simple, but analyzing the collected data is complex and intensive. If you’re an asphalt technician or engineer, that’s where RAAT-Pack has your back.

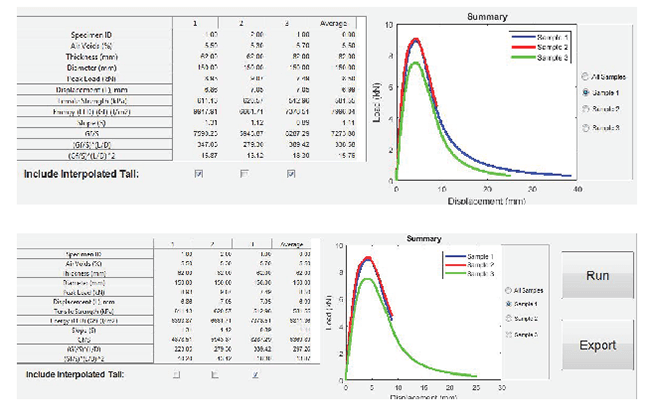

Senior laboratory engineer Edwin Haas, one of the RAAT-Pack’s creators, is seen here conducting an IDEAL-CT test. Users of the software can export a summary of results as shown on the screenshot below. Photo: ©Rutgers CAIT/Pavement Resource Program.

Developed by engineers in CAIT’s Pavement Resource Program (PRP), this software program is a prime example of how our experts continually seek ways to make daily tasks easier, faster, and more efficient for DOTs and other agencies faced with the daunting job of caring for our roadways.

RAAT-Pack software alleviates the burden on pavement technicians to do complex math and calculus. At the same time, it allows for batch analysis, helps analyze data far more quickly, and minimizes operator errors. All of this leaves more time for the actual rigorous testing and quality control.

The RAAT-Pack installer package includes the program, step-by-step instructions for each test, and sample input files that help guide users. The program runs on Windows operating systems. It is provided to end users as an executable GUI file built using the Matlab language. The installer package includes the specific version of Matlab Runtime that is needed to run the program correctly.

Rutgers Office of Research Commercialization is investigating the potential market for RAAT-Pack. As a pilot project, currently several agencies have use of the software, including New Jersey DOT, Maryland State Highway Administration, Virginia DOT, Port Authority of New York & New Jersey, and roughly 10 paving contractors.

For Cold-SCB tests, the program automatically calculates the required fracture energy for the curve and creates the interpolated “tail” required by the test specification. There is an option to deselect the tail data and to calculate the end values without the tail.

If you’re interested in RAAT-Pack, email Edwin Haas, senior laboratory engineer, CAIT Pavement Resource Program, or call him at 848-445-9168.

June 2019

Cold-temperature Semi-Circular Bend (CT-SCB) determines the low-temperature crack resistance of asphalt pavements. The test uses half-moon-shaped asphalt sample. Low-temperature crack resistance is calculated based on the fracture energy and post peak-load response.

The program automatically calculates the required fracture energy for the curve and create the interpolated “tail” required by the test specification for the data. There is an option to deselect the tail data and to calculate the end values without the tail.

Intermediate-temperature Semi-Circular Bend (IT-SCB) is an innovative crack-resistance test for asphalt pavements. Loading is applied to a half-moon-shaped asphalt sample in which a crack has been initiated

The sample’s further resistance to cracking can be determined by analyzing the fracture energy and post peak-load response.

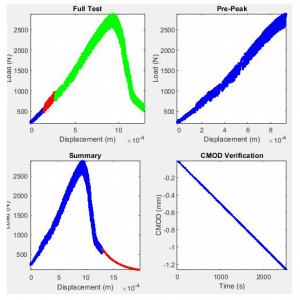

Direct Compaction Tension (DCT) is a low-temperature test for crack resistance. A circular specimen with a single-edge notch is loaded in tension to determine fracture energy, which is an indicator of fracture resistance.

Asphalt Pavement Analyzer (APA) is named for a machine with a steel wheel that rolls back and forth over a sample; a rubber hose is inserted between the steel wheel and the sample, better simulating traffic loading. The APA test is used to determine early-life rutting potential for asphalt pavements.

High-temperature Indirect Tensile Strength (HT-IDT) is similar to standard indirect tensile-strength testing, modified to use higher conditioning and testing temperature. The method loads a cylindrical sample across its vertical diametral plane until failure. Peak load at failure is then used to calculate the IDT strength of the asphalt pavement.

Rutgers IDEAL-CT is a crack-resistance test that uses a full-size Superpave gyratory-compacted sample and line loading. Crack resistance is calculated using the fracture energy and post peak-load response with no sample manipulation necessary.