Students from NJIT and Rutgers not only gained important experience outside of the classroom, but also learned the value of collaborating when they teamed up to help prepare The BEAST for a new highway bridge specimen.

Rutgers CAIT poured the concrete for The BEAST’s new project, a bridge deck specimen sponsored by the Federal Highway Administration, earlier this month. The project marks an important milestone in the life of The BEAST. Photo ©Michael O’Connell.

Research at The Bridge Evaluation and Accelerated Structural Testing lab (The BEAST) at Rutgers will provide data to identify optimal preservation and rehabilitation techniques, materials, and management strategies 30 times faster than field monitoring and will potentially save billions of dollars in infrastructure costs.

As the USDOT Region 2 University Transportation Center (UTC) consortium, Rutgers Center for Advanced Infrastructure and Transportation (CAIT), always envisioned The BEAST as more than just an innovative facility that can estimate the lifespan and performance of bridge systems and materials. But, also as an opportunity for students to receive experiential learning through a number of research projects and student experiences that piggyback on the ongoing and future accelerated testing efforts within the BEAST.

Earlier this month we realized this vision, when Rutgers CAIT poured the concrete for the deck of a full-scale steel girder bridge within The BEAST as part of a project sponsored by the Federal Highway Administration (FHWA). During the course of a six-hour day earlier in July, workers poured the concrete. Meanwhile, students from Rutgers and The New Jersey Institute of Technology (NJIT) joined to advance the effort for FHWA and several leveraged research projects.

Matt Bandelt and Matt Adams, both assistant professors of Civil and Environmental Engineering at NJIT and co-directors of the Materials and Structures Laboratory (MatSLab), said The BEAST provided students with a chance to see the bigger picture about infrastructure projects.

“The NJIT research students are regularly exposed to physical experimentation and numerical simulation of civil infrastructure materials; however, working on a project with The BEAST provides a unique learning opportunity for them,” they said. “The BEAST laboratory brings researchers together to solve complex problems regarding the design, maintenance, and preservation of bridge infrastructure. Such an experience helps our student researchers look beyond their individual projects and instead at the wider challenges our profession faces.”

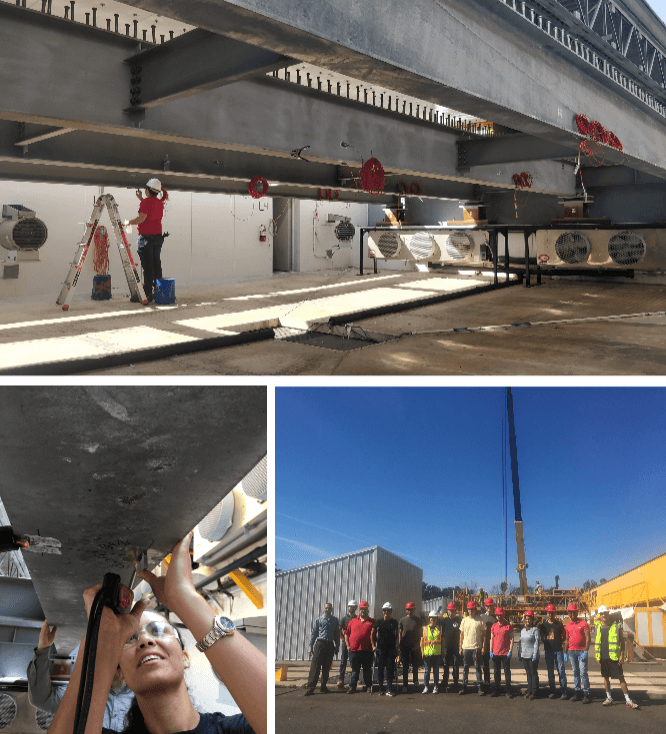

Students have contributed a lot to The BEAST so far. Pictured is (Top) Andre Marques, Undergraduate Student; (Bottom Left) Adriana Trias, PhD Student; and (Bottom Right) a group photo of Rutgers and NJIT students. Photos ©Shane Mott and Ryan Stiesi.

On site, students prepared different companion-material specimens that will be tested at NJIT’s MatSlab, they said. Students are collecting data to analyze the concrete materials used in the bridge deck of the BEAST specimen. Specifically, they are looking into the mechanical properties, such as compressive strength, and durability properties, such as freeze-thaw resistance, of the concrete.

The results will be used to help both Rutgers and NJIT, as well as other UTC partner universities such as SUNY-Buffalo, Princeton, and Columbia, analyze the deterioration performance of the full-scale BEAST specimen, Bandelt and Adams said. Over several months, the NJIT team has already been conducting preliminary testing at MatSLab to help Rutgers CAIT develop an environmental-conditioning plan for this specimen.

“This collaboration allows student researchers to share and receive knowledge with other students who are gaining expertise in different research areas,” they said. “We believe that students from both universities benefit by seeing how their projects fit together to advance the state of knowledge on infrastructure performance and deterioration.”

Shane Mott, a project manager at Rutgers CAIT, has been working to get the facility ready for this project. He said The BEAST is a one-of-a-kind lab, and that pouring the concrete deck was an important step toward analyzing the bridge specimen and being able to learn from the data it generates.

What makes The BEAST unique is that it can simulate approximately 15 years’ worth of deterioration on the bridge in just a matter of months. No other facility has that unique capability, which opens up the doors for a variety of future projects to take place.

Leading up to this, the team worked directly with FHWA to find out what design materials would best meet their needs, Mott said. They are looking to create a representation of the “median” bridge today—something built around the 1980s.

“For our particular bridge we are looking for something that is a good representation of a lot of the bridges that are out there and exist today, and are staring to show signs of advanced deterioration,” he said.

With Dr. Franklin Moon, a Professor in The Department of Civil and Environmental Engineering at Rutgers, leading the project they soon moved from brainstorming to building. First, they prepared the facility itself to make sure it was up to speed for the actual testing. They then contracted with Ron-Jon Construction Corp. (who teamed with Susan R. Bauer, Inc. and Berto Construction, Inc.), to construct the specimen as per current best practices.

Rutgers faculty and students began adding gauges and sensors to the BEAST specimen as the construction progressed. These devices will be used to collect Structural Health Monitoring (SHM) data throughout the bridge specimen’s life-cycle, Mott said. The team will gain an overall picture of the health of the bridge’s structural elements over the course of the project. They will also conduct Non-Destructive Testing (NDT) to get a more localized idea of the deterioration. All of this will be in addition to the materials testing being done by NJIT.

“We should be able to learn a lot,” Mott said. “To be able to see a bridge born and die all within a short period for us as humans has not been done on this level before.”

The day of the concrete pour went well, Mott said. Now they are waiting on the concrete to fully cure before starting tests that will include driving the rear carriage of a tractor trailer back and forth on the specimen, freeze-thaw cycles, and spraying it with different chlorides and de-icing chemicals, all of which will cause the specimen to begin to deteriorate.

The concrete was poured over the course of a six-hour day. Photo ©Michael O’Connell.

He said reaching this milestone is important.

“It felt good, a lot of people have been waiting excitedly to get this thing started, and the fact that we are finished with the first specimen, it feels really good,” Mott said. “I’m personally excited to see what we can learn from this. Nothing like this has ever been done at this scale before, there’s a lot of value that can come from this project—and hopefully we’ll learn just as much from the next bridge specimen.”

Bandelt and Adams said they plan to continue providing input to Rutgers, FHWA, and anyone else who is interested in new systems that can be tested in The BEAST in the future.

They said that these materials will be used in future generations of bridge infrastructure, and will help provide longer service lives and reduce maintenance needs for bridge owners.

“The collaboration between the Rutgers-CAIT team and NJIT provides a diverse expertise to research sponsors in the areas of asset management, non-destructive evaluation, structural engineering, and mechanics and durability of civil infrastructure materials,” they said. “This collaboration benefits both academic institutions, the research sponsors, and ultimately the end-users of this research through improvements in infrastructure over the long-term.”